Snapmaker just announced a brand-new 3-in-1, 3D printer at Consumer Electronics Show (CES) 2020: the Snapmaker 2.0. The new model improves on its successfully produced 2017 Kickstarter campaign, the Snapmaker 1.0. But is the Snapmaker 2.0 a worthy successor to the original?

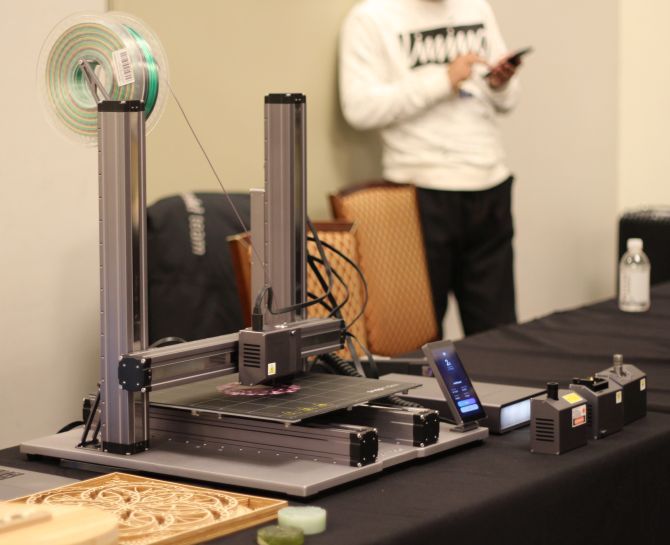

The 2.0 model is unique among 3D printers in that it combines three different DIY technologies into a single basket: laser engraving, CNC machining and 3D printing. The uses three modular, replaceable heads. One prints using a variety of filaments, another does CNC machining (or routing), and the other possesses a powerful laser for making engravings.

The heads switch out easily between engraving, CNC machining (or carving), or 3D printing modes. Interestingly, the printer can carve into notoriously tough materials, like jade (which is the toughest natural material in the world). It can also process wood, aluminum, glass, and many other materials.

The price is high at somewhere between $800 and $1,200. However, similar Kickstarter projects have launched at around $800 and only offered one of the three creation modes, such as the Creation Station. The Snapmaker's three different modes make it far and away a better deal---which explains why it managed to become the third most-funded 3D printer on crowd funding platforms. While Kickstarter campaigns put all the risk on the buyer, Snapmaker has already proven itself by successfully funding its first printer. Its second printer racked up even more money and currently sits at close to eight million dollars in funding. It is the most-funded technology project in Kickstarter history.

Part of the reason both iterations of the Snapmaker sold so well are their high-quality, all-metal chassis, ease of construction, and value. When the Snapmaker first entered the market there were no serious competitors at the same price point. That's doubly true even now.

As far as I can tell, there aren't many differences between the original and its upgraded version. For example, the original Snapmaker also included three heads and modes, a wireless remote control, and modular components which they claim allows for assembly in 10 minutes. (The fast assembly time compares favorably with many Prusa i3 clones, which can take hours to set up and configure. Although 10-minutes of construction time is still longer than that of the preassembled 3D printers.)

The biggest differences are in the size of the build platform and the price. While the original Snapmaker made its name by offering a three-in-one 3D printer for the absurdly low price of $300, the newest model is a far cry from that price point. $800 for a preorder on a large-bed 3D printer would be a great deal---but it's clear that Snapmaker no longer has interest in producing high quality printers in a low-price market. And the full retail price is close to $1,800 for the entry-level model.